|

|

|

|

|

|

|

|

| |

|

With

our regular R & D in technology, we

have developed Prototype-Tablets, to enable

our esteemed customer to hold in their

hands amazingly,

|

|

| real

prototypes of the new tablet products. The

prototype tablets are made from a special

composition material, which will help you

to take a final design of the tablet, before

the master hob is made.This latest technology

allows you to see the tablet's actual shape,

colour, lettering, monograms or logo to

be previewed quickly and inexpensively. |

|

| |

|

|

|

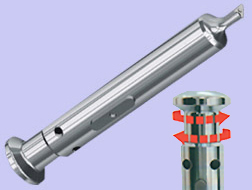

All

shaped and multi-tipped upper punches

are keyed to prevent the punch from

rotating, so that the tip is permanently

aligned with the die - however, this

often causes localized headwear at

the position where the head contacts

the cam track. |

| To

combat the concentrated wear on the

punch head, we have developed a shaped

punch with a rotating head This rotational

action evenly distributes wear on

the head thus significantly increases

the life of punches and cams |

|

| The

Rotational head tooling concept can be applied

to most standard punch types and on both

upper as well as lower punches. |

|

|

|

|

|

|

|

| Hard

Chrome Plating |

| Ideal

for resisting wear and corrosion in

many standard applications. HCP has

a low coefficient of friction resulting

in good non-stick properties.

|

|

| |

| Nodular

Thin Dense Chrome |

| NTDC

can be applied to the entire punch

and face and has the added benefit

of FDA approval for use with full

contact parts. |

|

| |

| Titanium

Nitride Coating |

| TiN's

main application area is wear protection.

However, it also offers the advantages

of hardness, corrosion resistance

and high-temperature resistance.

|

|

| |

| Chrome

Nitriding |

| CrN

offers similar properties to those

TiN in terms of corrosion, oxidation

resistance and hardness , but it has

the added benefit of a lower friction

coefficient. |

|

| |

|

| Ion

Implantation |

| Ion

Implantation can improve wear, corrosion and

oxidization resistance, hardness and fatigue

strength. It can also lower the friction, which

results in reduced pickup and sticking. This

special coating is recommended mainly for Stainless

Steel material tooling. |

|

|

|

|

|

|

|

|

|

|

|

|

|